The Greatest Guide To Storefront Panels

Table of ContentsThe 7-Minute Rule for Spandrel Panel WindowRumored Buzz on Spandrel PanelThe Buzz on Spandrel Panel Curtain WallFacts About Spandrel Panel Curtain Wall Revealed

Whether you require Polishing Infill Panels, Spandrel Panels, Darkness Boxes, Soffits, Copings, Backpans or Flashings, Embury Business will supply in a timely manner and on budget plan. Allow our group aid and also overview you via all of you metal panel demands. Our Cutting-edge Facilities enables us to work effortlessly with any kind of sort of material and also obtain you what you need.

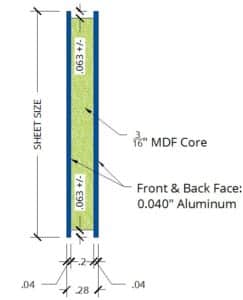

The panels are offered from.016 to 3/16 (.1875) of an inch, utilizing Aluminum, Stainless Steel, Galvanized or ACM. Whatever the density, material or finish Emburite Panels will answer the requirement.

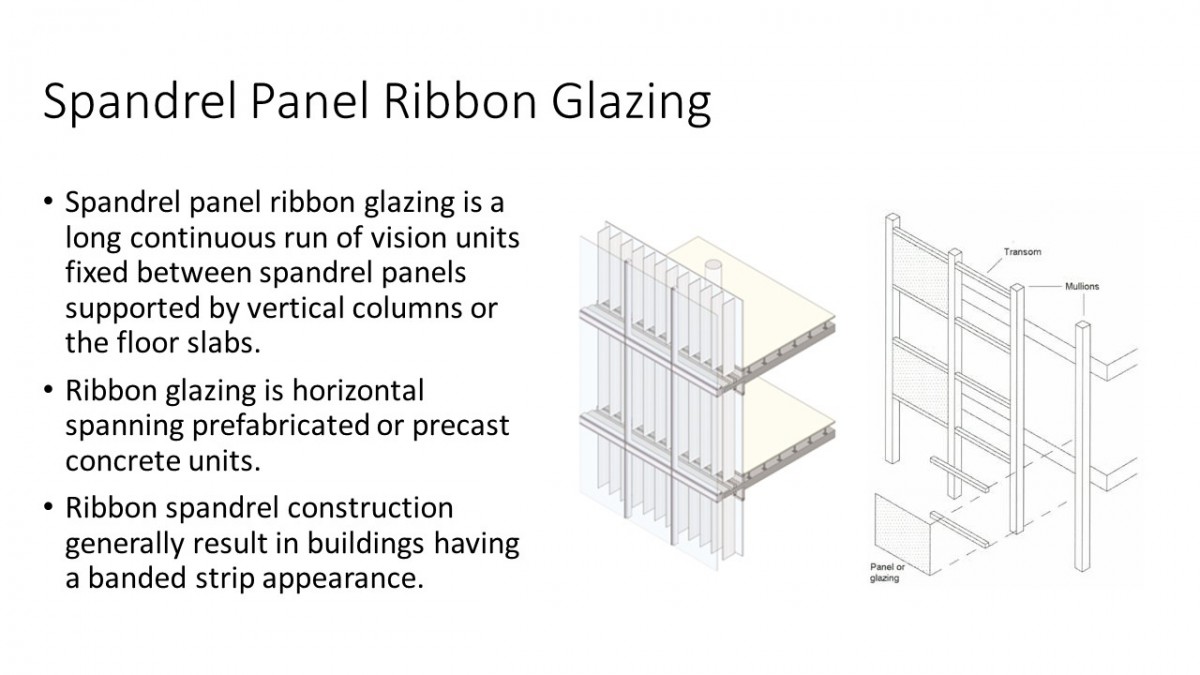

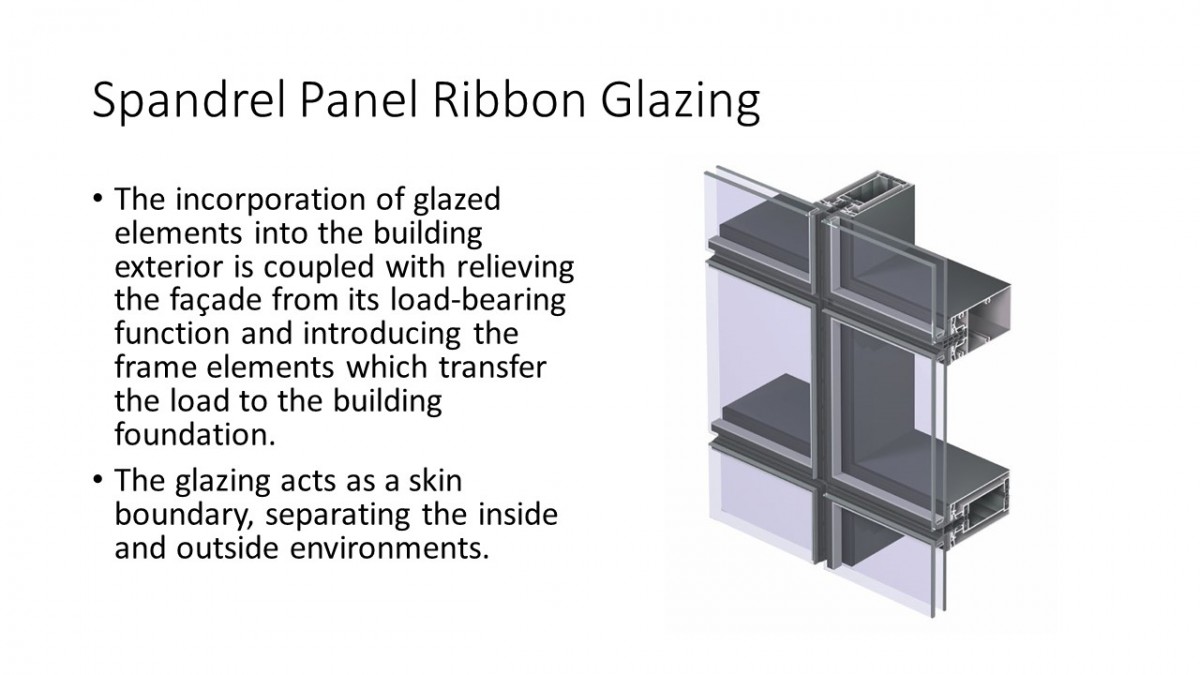

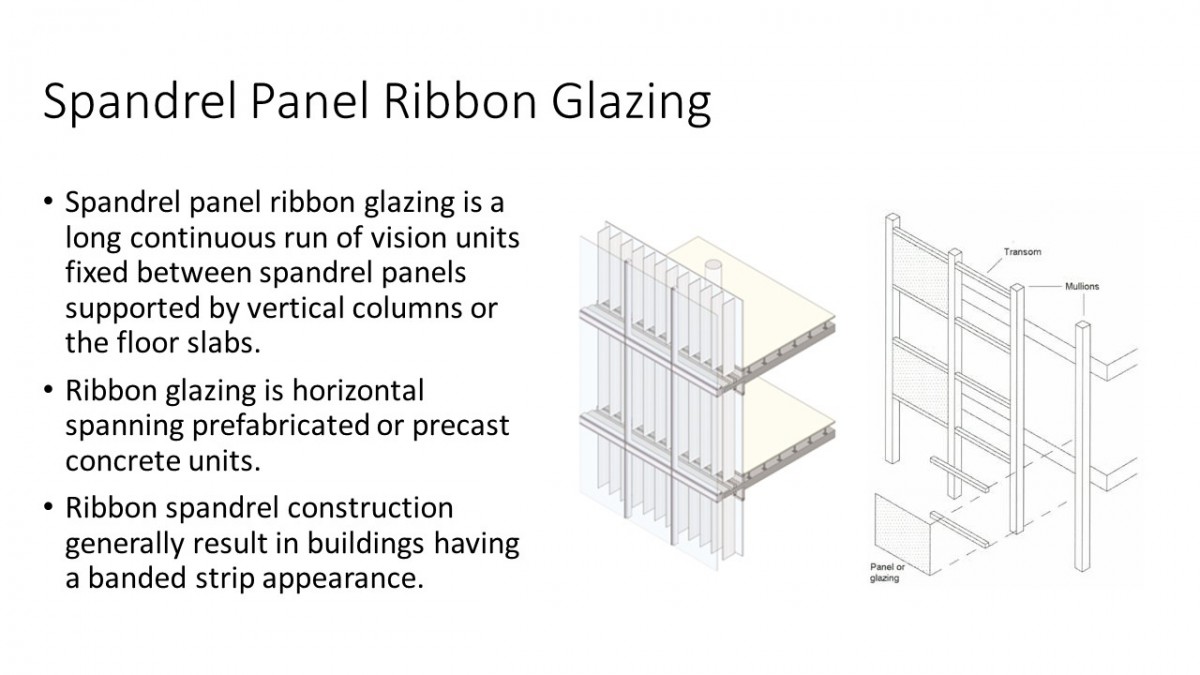

The initial significant instance of the style was the Equitable Cost Savings & Finance Structure in Rose city, Oregon performed by designer Pietro Belluschi in 1948. As the world's very first fully enclosed cool building, this sleek 12-story framework rapidly set the pattern for lots of post-WWII skyscrapers and tiny range office complex. The drape wall system is made up of a repetitive grid of upright extruded aluminum mullions as well as horizontal rails.

Some Of Spandrel Panel Window

These spandrel panels can be available in a range of products. Early spandrel panels were made from heat-strengthened opaque glass fused with colored ceramic. The Pittsburg Plate Glass Firm made the glass panels under the profession name "Spandrelite," and offered eight common colors. The Libbey-Owens-Ford Firm offered sixteen shades alternatives under the "Vitrolux" brand.

Taken into consideration appropriate for practically any dimension commercial, government or institutional structure, the Curtain Wall design came to be widespread by the early 1950s. Several post-WWII buildings of varying designs also integrated drape wall systems into some exteriors however are not considered Drape Wall surface style unless the bulk of the visible exteriors are so constructed.

Therefore, light-weight materials can be used in their development. Commercial glazing systems are typically constructed of aluminum-framed walls with glass, metal panels, louvers, operable home windows or vents, or rock veneer infills. Structure envelope specialists will usually glazing glass cutting machine encourage designers on drape wall and also storefront needs for developing movement, thermal expansion and contraction, water diversion, and thermal performance.

The Best Strategy To Use For Spandrel Panels Cladding Timber

Condensation formation on spandrel infill is more than likely to take place during extreme wintertime conditions when inadequate heat is provided from the interior to stop indoor infill surface temperature levels from staying above the dew factor. When interior surface area temperatures dip listed below the humidity, water particles begin to base on the interior surface of the spandrel infill.

Need to improperly created spandrel conditions be left ignored, condensation can result in dampness or visual damage to the spandrel panel and/or indoor surfaces. When condensation types at the spandrel infill of a glazing system, several kinds of damages can occur, as well as the effects of condensation can be far-ranging. In enhancement to wetness damage and also microbial development, condensation growth on spandrel infill can likewise have an adverse result (spandrel panel curtain wall).

One method to postpone the formation of condensation on the glazing system spandrel infill is to use the building COOLING AND HEATING system. By increasing air movement near i loved this these locations, even more warmth will be moved to the setting up as well as increase interior surface temperatures. An additional method to use the HEATING AND COOLING system is by reducing the interior relative moisture set points with regard to outdoors temperature.

An additional method of preventing condensation is by securing the horizontal-to-vertical mullion joints at the spandrel cavity to avoid unrestrained air movement right into the tooth cavity. Generally, an uncontrolled interior is moisture packed and also when it enters into call with the spandrel infill, which is below the humidity, it increases the amount of condensation formation.

Some Known Details About Spandrel Panel Detail

Along with incorporating recovery approach, means to minimize condensation potential throughout design consist of: Usually curtain wall surface systems have higher resistance to condensation than store front systems. Making use of curtain wall surface is one method to minimize, or delay the beginning of condensation formation. At Pie, we provide 2-D thermal modeling (THERM) to aid our clients with the style of spandrel areas.

By recognizing surface area temperature levels, Pie is able to determine under which problems condensation will take place, in addition to identify change factors at which condensation will certainly not develop, making it easier to predict as well as remediate. Furthermore, various configurations can be modeled to make the most of indoor surface temperatures. Setting up back pans right into the spandrel infill glazing pocket, which are aired vent to the outside with insulation outboard of the pan, promotes increased indoor surface area temperature levels with the added benefit of reducing warmth transfer through the additional reading spandrel infill.